Company Profile Company Profile

HARESAN was established in 2006, specializing in monochrome LCD, TFT, AMOLED small and medium-sized display touch modules, research and development, production, marketing Sales, after-sales service as one of the national high-tech enterprises.

The company currently has more than 1200 employees,with Yichun as the manufacturing base and a market center and technology center established in Shenzhen Establish sales branches in Beijing, Shanghai, and Nanjing.

About UsCompany History

● 2006: Shenzhen Huaersheng Electron was established

● 2010: The first TFT module line was mass-produced

● 2014: The first AMOLED line was mass-produced

● 2017: Jiangxi Huaersheng was established

● 2018: Shenzhen factory relocates to Jiangxi

● 2019: Approved by Panasonic & ISO14001

● 2021 : BOE & Visionox Approved

● 2022: Xiaomi Supplier Approved & IATF16949 & QC080000

● 2023 : Hualin Industrial Park officially put into operation

About UsCompany Scale

1. The company grew rapidly, from ¥50 million in 2017 to ¥120 million in 2018, ¥190 million in 2019, ¥320 million in 2020, ¥400 million in 2021, and ¥530 million in 2022, it has achieved sustained leapfrog growth, with an annual compound growth rate of more than 50%;

2. The company has 2 STN Panel Production Lines, 15 automatic COG production lines, 5 automatic COF production lines;

3. The company is based on seiko manufacturing, skilled in technology research and development and quality control, the company has more than 1,200 people, including more than 120 technical personnel, more than 180 quality personnel,Technical and quality team personnel accounted for more than 25%

530 Million

2022 Turnover

1,200Workers

Excellent Team

20 lines

Full-automatic Production Line

About UsManufacturing Capability

530 Million

Monochrome LCD panel

2 fully automatic production lines, panel size 370mm*470mm, Can undertake customized solutions for black and white screen products in the range of 1.0”-10”.

6.8KK/M

COG module

19 fully automatic production lines, capable of producing 0.5"-8"TFT/Mono modules.

2.2KK/M

COF module

6 fully automatic production lines, panel size 370mm*470mm, Can undertake customized solutions for black and white screen products in the range of 1.0”-10”.

About UsR&D Capability

Technical staff 120+

We have over 50 technicians with more than five years of experience, over 20 technicians with more than ten years of experience:

Vacuum potting ultra-narrow frame technology

Vacuum potting is a process in which liquid potting material is mechanically injected into a mold equipped with a module device under vacuum environment and solidified under normal temperature or heating conditions.There is a sealed border in the assembly product to strengthen the reliability and sealing of the product,which can achieve the role of more than 5ATM waterproof requirements;

The appearance can also be extremely narrow border.

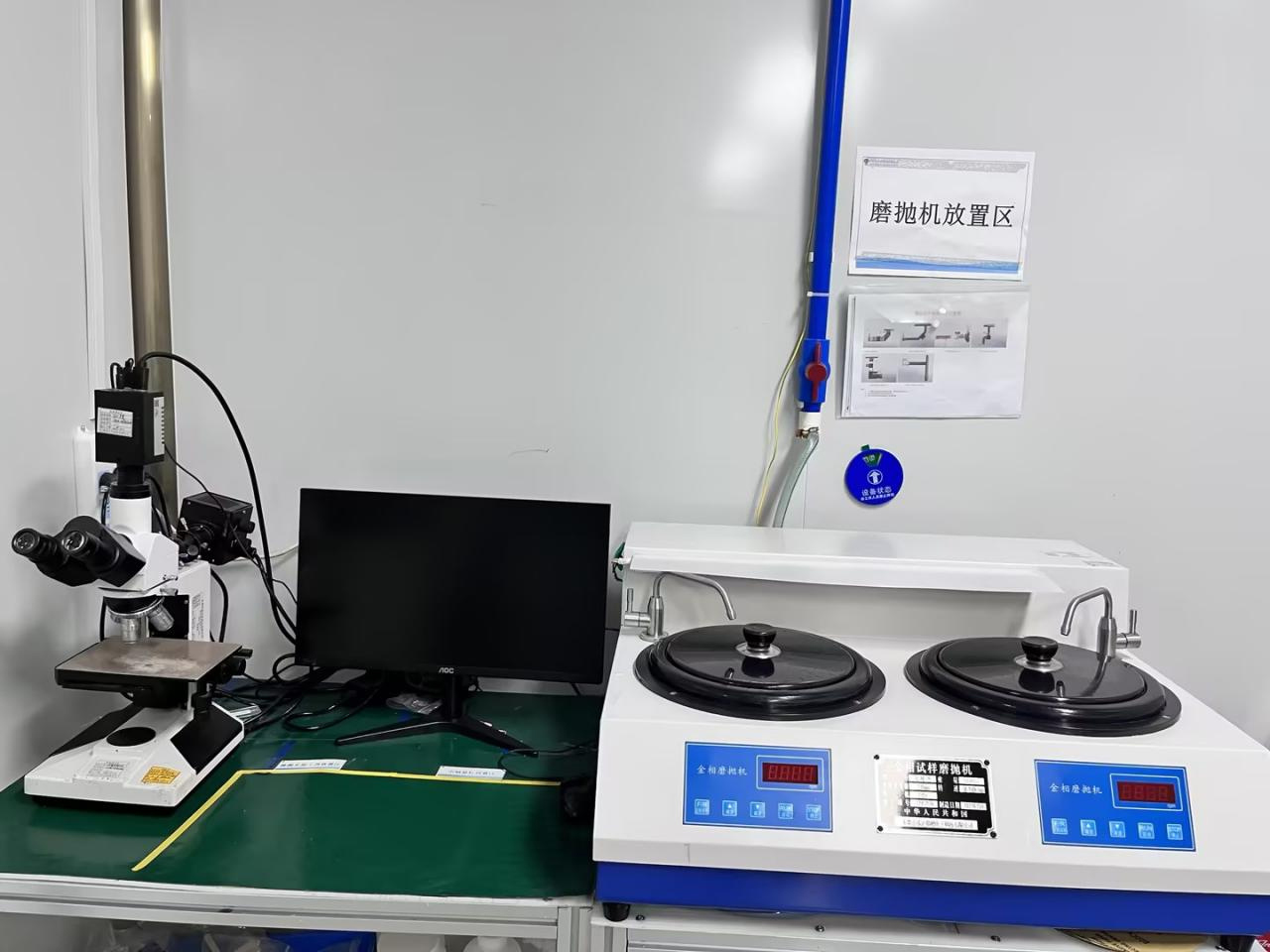

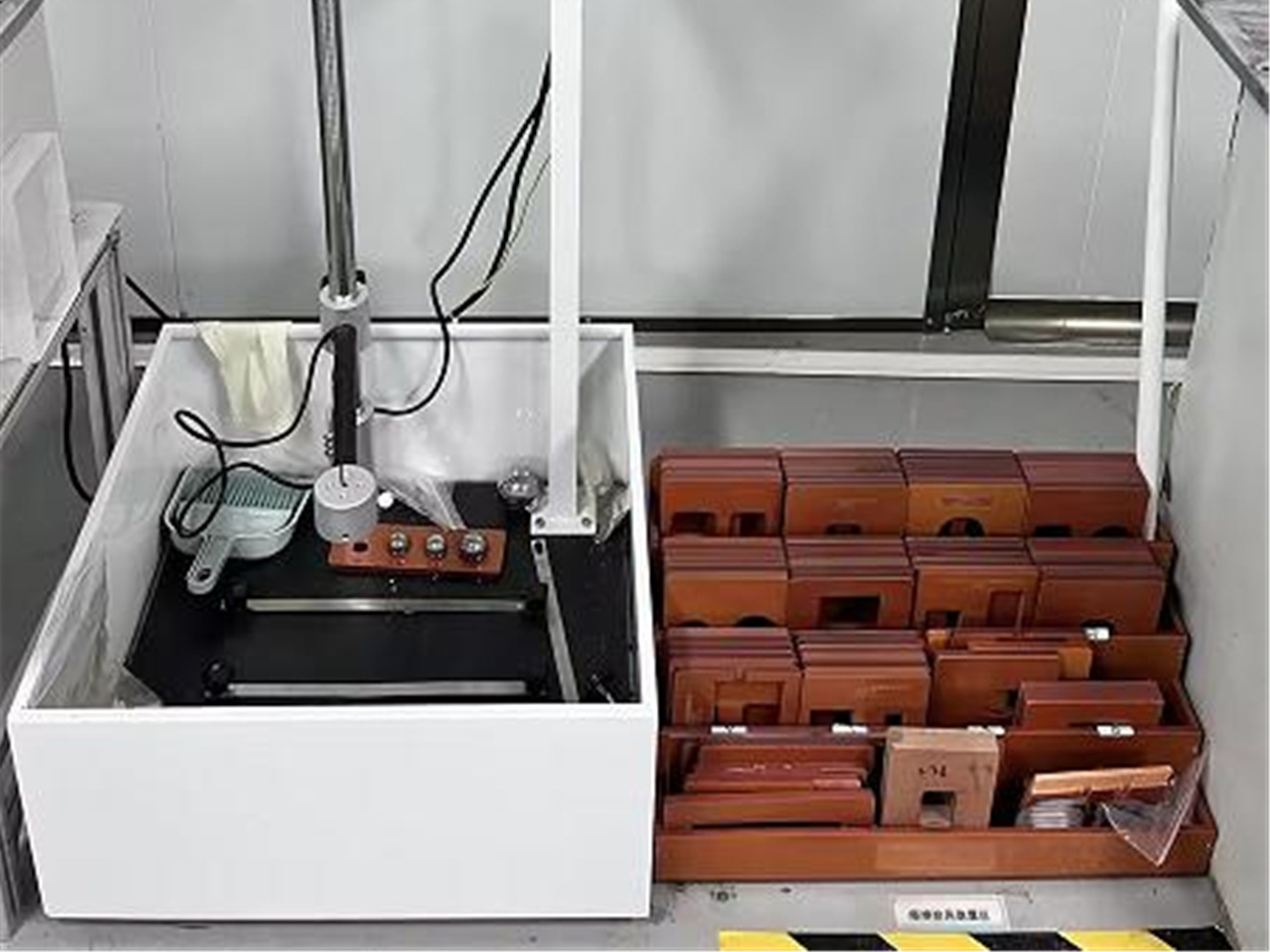

About UsQuality is the lifeline of an Enterprise

Quality is the life of the enterprise, The company has established a quality team of over 180 people, company manpower accounted for more than 15%.

To achieve process oriented digital construction, the first phase will invest over ¥ 3.8 million to build an MES system,At present, all production has been digitally monitored to ensure quality assurance.

Company has passed ISO9001, ISO14001, IATF16949, QC080000 multiple certifications. Through multiple measures, the quality continues to improve, with a total delivery volume of over 50KK for the whole year of 2022 and a quality batch pass rate of over 95%.

sales@hemoled.com

sales@hemoled.com +86 18926513367

+86 18926513367